Search This Supplers Products:Plastic recycling pelletizing machinePlastic corrugated pipe machinePlastic crusherPlastic label remover

Waste Plastic PE PP Bottles Recycling Crushing Hot Washing Line/Machine with metal detector

- group name

- Plastic PET Bottles Recycling Washing Line

- Min Order

- 1 set

- brand name

- EVERGRAND

- Nearest port for product export

- Qingdao, Tianjin, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Westem Union

- update time

- Thu, 27 Feb 2020 12:49:58 GMT

Paramtents

After-sales Service Engineers available to service machinery overseas

Capacity 200-1000kg/h

Motor brand Shanghai Dasu or siemens

Final Flake Humidity less than 3%

Material of washing part Stainless steel

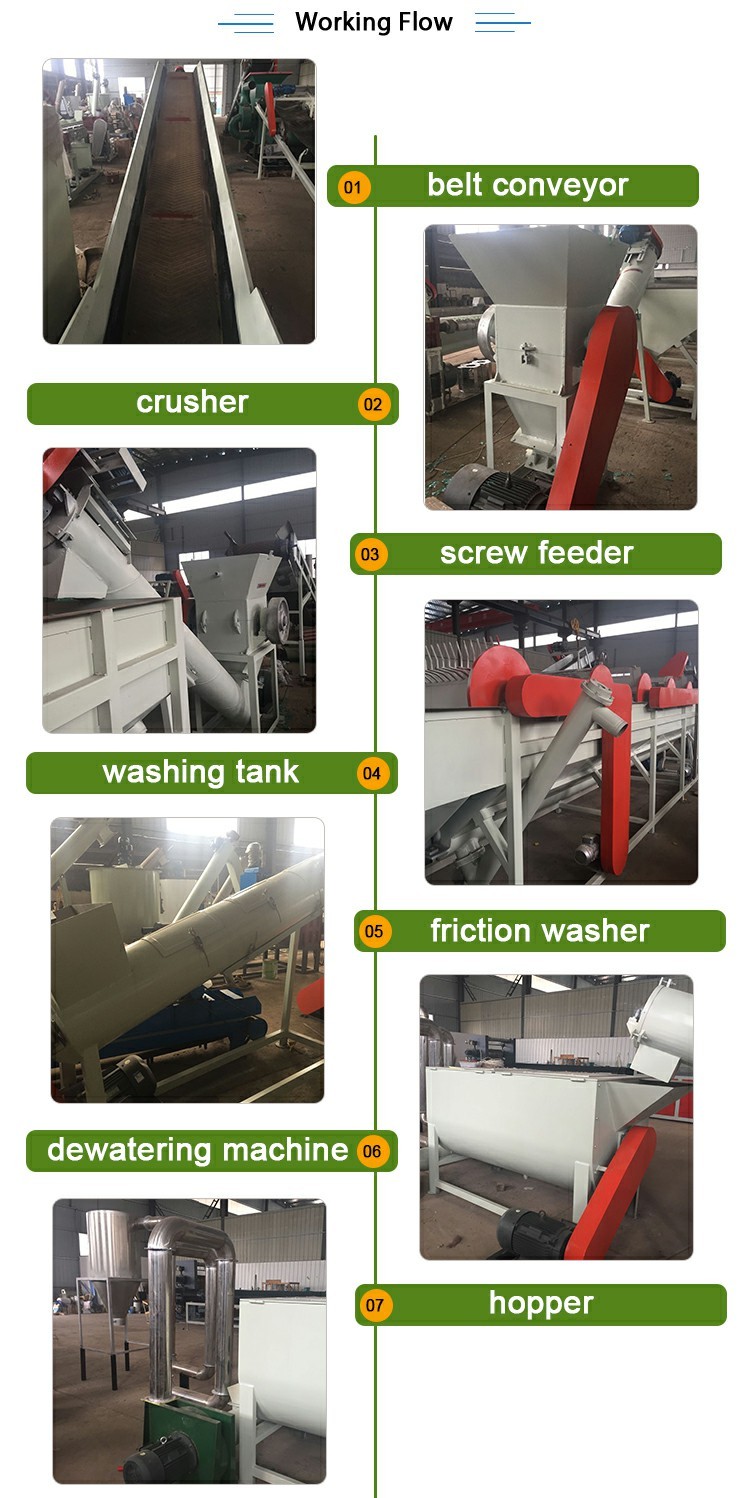

Application used for plastic film/woven bag/shopping bag crushing and washing

Washing type hot washing or cold washing

MOQ 1set

Packging & Delivery

-

Min Order1 set

Briefing

Try best to reduce your cost on labor

Good quality with reasonable price

Long lifespan

Lower power consumption

Good quality with reasonable price

Long lifespan

Lower power consumption

Detailed

Waste Plastic PE PP Bottles Recycling Crushing Hot Washing Line/Machine with metal detector

Capacity(kg/h) | 300 |

500 |

1000 |

2000 |

Motor power(kw) | 22 |

37 |

75 |

110 |

Screen hole size(mm) | 26 |

34 |

46 |

60 |

Final humidity | Less than 3% |

Less than 3% |

Less than 3% |

Less than 3% |

Water supply(tone/h) | 3 | 4 | 6 | 9 |

Material | stainless steel | stainless steel | stainless steel | stainless steel |

Total length(m) | 24 | 26 | 30 | 34 |

1. The whole line capacity between 150kg/h-2000kg/h (150kg/h, 300kg/h, 500kg/h, 1000kg/h, 2000kg/h).

2. Parts which contact material use SUS304, thickness more than 3mm, ensures whole washing line with long service life time.

3. World famous brand components applied on the production line- SKF bearing, Siemens contactor, Japan RKC temperature, ABB invertor, Siemens PLC control.

4. The whole production line with CE certification, ISO9001 certification.

2. Parts which contact material use SUS304, thickness more than 3mm, ensures whole washing line with long service life time.

3. World famous brand components applied on the production line- SKF bearing, Siemens contactor, Japan RKC temperature, ABB invertor, Siemens PLC control.

4. The whole production line with CE certification, ISO9001 certification.

1.We will delivery the machine and provide the bill of load on time to make sure you can get the machine quickly

2.When you finish the Preparation conditions,our fast and professional aftersales service engineer team will go to your factory to install the machine,give you the operating manual,and train your employee until they can operate the machine well.

3. We often ask feedback and offer help to our customer whose machine have been used in their factory for some time.

4.We provide one year warranty

5.Well-trained & experienced staff are to answer all your inquiries in English and Chinese

6 .24 hours for engineer response (all services part 5days in customer hand by Intl' courier).

7 .12 Months guarantee and life-long technical support.

8.Your business relationship with us will be confidential to any third party.

9. Good after-sale service offered, please get back to us if you got any questions.

2.When you finish the Preparation conditions,our fast and professional aftersales service engineer team will go to your factory to install the machine,give you the operating manual,and train your employee until they can operate the machine well.

3. We often ask feedback and offer help to our customer whose machine have been used in their factory for some time.

4.We provide one year warranty

5.Well-trained & experienced staff are to answer all your inquiries in English and Chinese

6 .24 hours for engineer response (all services part 5days in customer hand by Intl' courier).

7 .12 Months guarantee and life-long technical support.

8.Your business relationship with us will be confidential to any third party.

9. Good after-sale service offered, please get back to us if you got any questions.