Search This Supplers Products:Plastic recycling pelletizing machinePlastic corrugated pipe machinePlastic crusherPlastic label remover

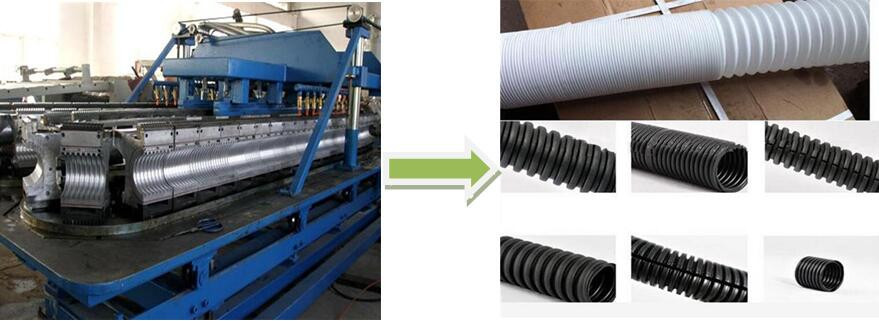

Hdpe Pp double wall corrugated pipe production line machine/extrusion line

- group name

- Double wall corrugated pipe production line

- Min Order

- 1 piece

- brand name

- EVERGRAND

- Nearest port for product export

- Qingdao, Tianjin, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Westem Union

- update time

- Wed, 20 Nov 2019 21:22:20 GMT

Paramtents

COLOR according to your need

original China

MOQ 1 set

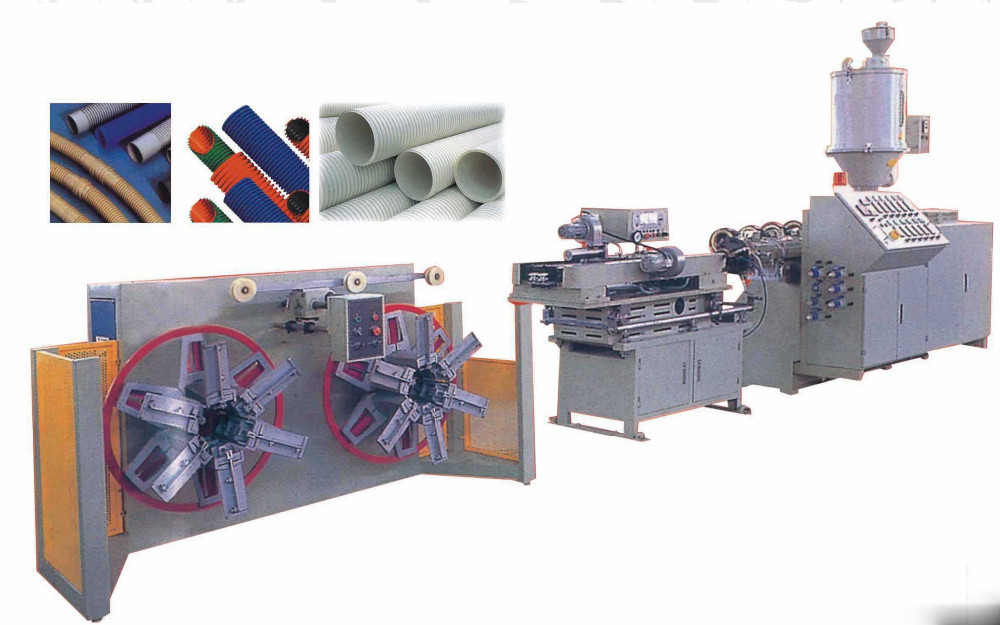

Production diameter 50-200mm

After-sales Service Provided Engineers available to service machinery overseas

Power(KW) 37-120kw

Usage plastic corrugated pipe

Automatic Grade Automatically

Packging & Delivery

- 500cm x150cm x180cm

-

Min Order1 piece

Briefing

Detailed

|

pipe diameter

|

4-12mm

|

10-32mm

|

25-65mm

|

50-110mm |

|

extruder

|

SJ-30/28

|

SJ-45/28

|

SJ-65/30

|

SJ-90/30 |

capacity | 20kg/h | 50kg/h | 120kg/h | 250kg/h |

|

produce speed

|

5-15m/min

|

10-20m/min

|

3-10m/min

|

1-5m/min |

|

mould blocks

|

42 pairs

|

42 pairs

|

42 pairs

|

50 pairs |

|

NO.

|

item

|

quantity

|

specification

|

|

1

|

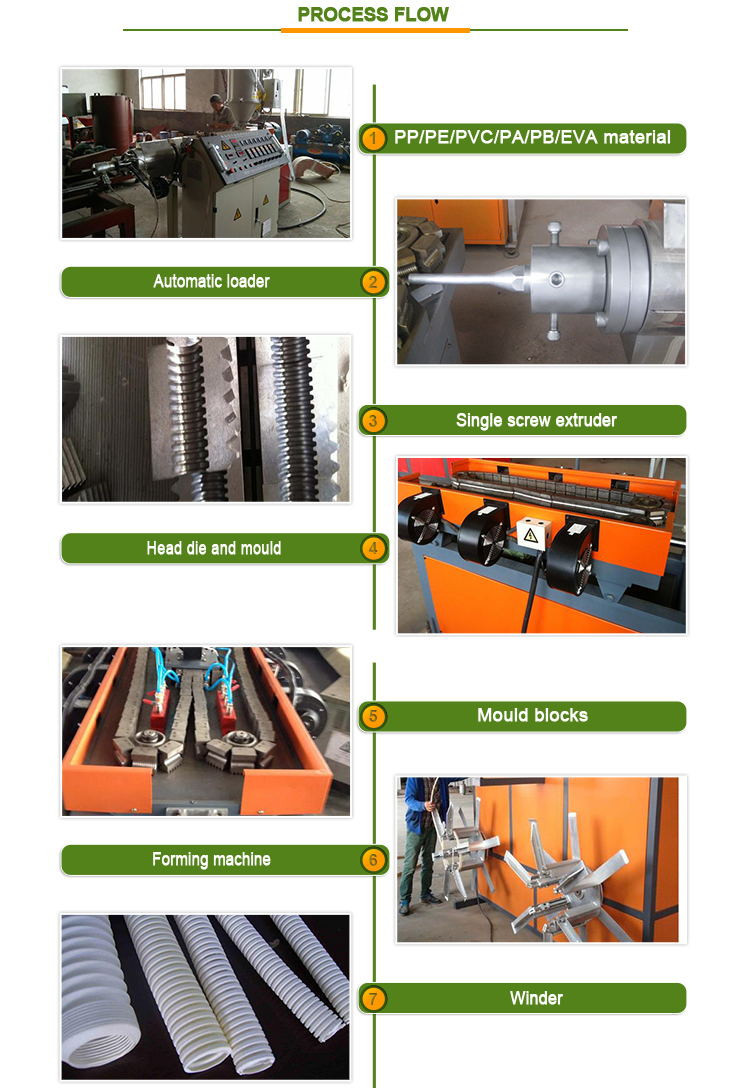

Automatic vacum loader Hopper dryer |

1

|

Loading method: Vacuum |

|

|

|

|

Contactor: Siemens Inverter: ABB or DELTA Temperature controller: DELTA |

|

|

|

|

Motor power:11Kw 15Kw 22Kw,37KW..,according to the extruder Siemens motor ,frequency convertor control |

4 | Die head | 1 | Material:40Cr |

1 | Forming mould material: 40Cr Quantity: 38 or 75 or 90 Pairs or according to your requirement | ||

1 | Motor power:4Kw Cooling method: fan blower or water cooling Transmission method is gear | ||

7 | Winder | 1 |

1. Different extruder size according to different size of hose.

2. Motor from famous brand.

3. Frequency convertor ABB brand.

4. High precision processing for each parts, never roughly manufacturing.