Search This Supplers Products:Plastic recycling pelletizing machinePlastic corrugated pipe machinePlastic crusherPlastic label remover

PE PP Plastic Hot Cutting Granulating Plant/Machine

- group name

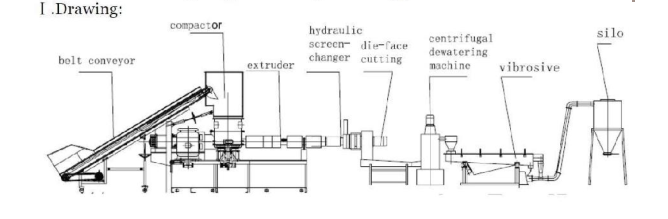

- Hot cutting with water ring pelletizing machine

- Min Order

- 1 set

- brand name

- EVERGRAND

- Nearest port for product export

- Qingdao, Tianjin, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Westem Union

- update time

- Wed, 20 Nov 2019 21:57:19 GMT

Paramtents

After-sales Service Provided Engineers available to service machinery overseas

Capacity 100-500kg/h

Raw material pp/pe/ldpe/hdpe film

Qulaity assured 2 years

color according to your requirements

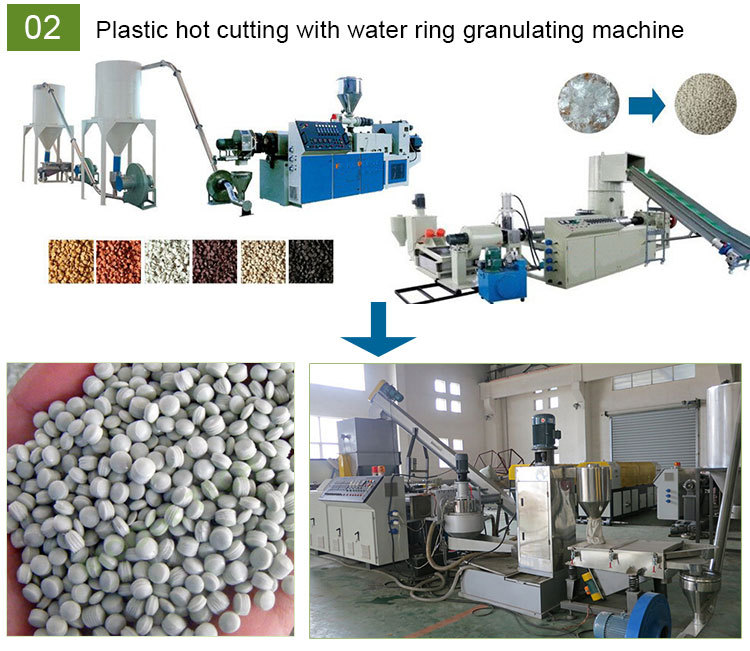

Load One 20 feet container

Packging & Delivery

-

Min Order1 set

Briefing

Good quality clean pp pe pellets

Long lifespan

Lower power consumption

Good quality with reasonable price

Long lifespan

Lower power consumption

Good quality with reasonable price

Detailed

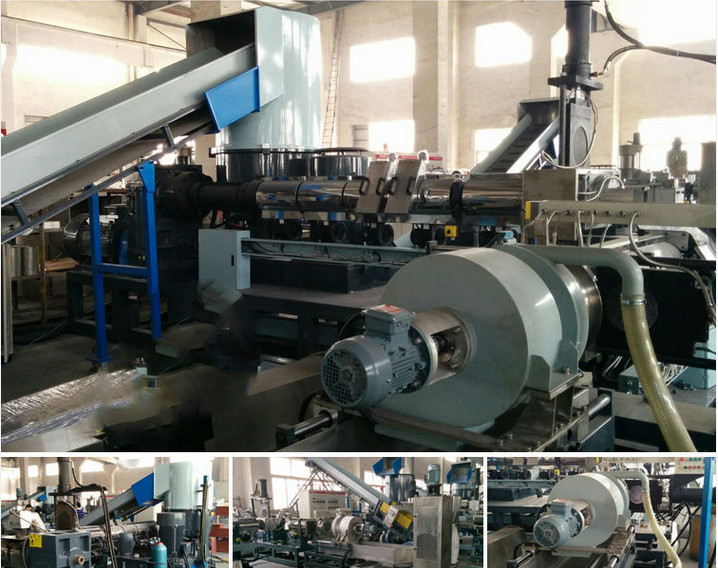

PE PP Plastic Hot Cutting Granulating Plant/Machine

This pp pe film pelletizing line is used torecycle and pelletize eva,pe,pp,xps,eps material wastes. It is the idea production line for recycling plastic film, silk, flakes, strips, bags and leftover wastes.

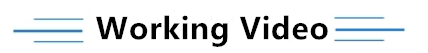

This type of recycling line is composed of loader, agglomerator ( or crusher), extruder, hydraulic screen changer, mould, water ring cut system, dewatering collecting system, air blowing and storing system etc.

Feature of plastic hot cutting with water ring granulating machine

- High efficiency force-feeder ensures high capacity feeding ,low energy consumption.

- Extruder of film granulation line :single stage ,double stage

- Single screw extruder, equipped with specially designed screw & barrel, venting system, has avery good output capacity.

Advantages of plastic hot cutting with water ring granulating machine

- Easy operation: it has automatic constant temperature control and stable performance.

- Low cost in using after redesign: now this kind machine is more economic in electric power source and also water.

- High output, long operating life and lower noise: it’s the ideal waste plastics regenerative pelletizer machine for nowadays.