Search This Supplers Products:Plastic recycling pelletizing machinePlastic corrugated pipe machinePlastic crusherPlastic label remover

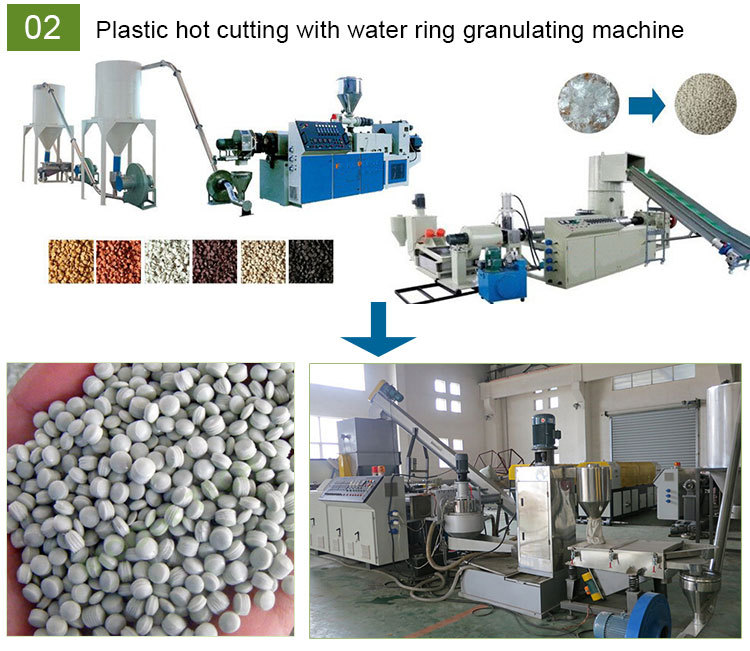

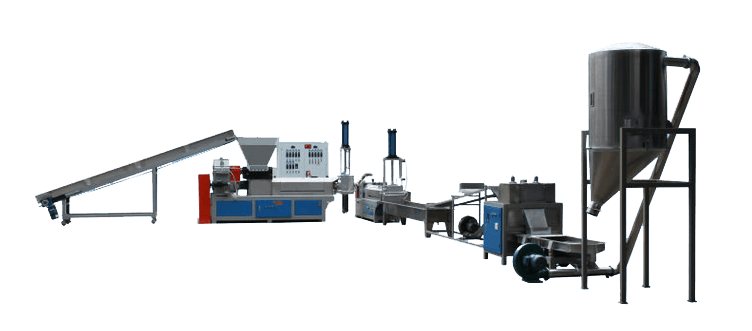

Full Automatic Granules Production Line/Granules Making Machine

- group name

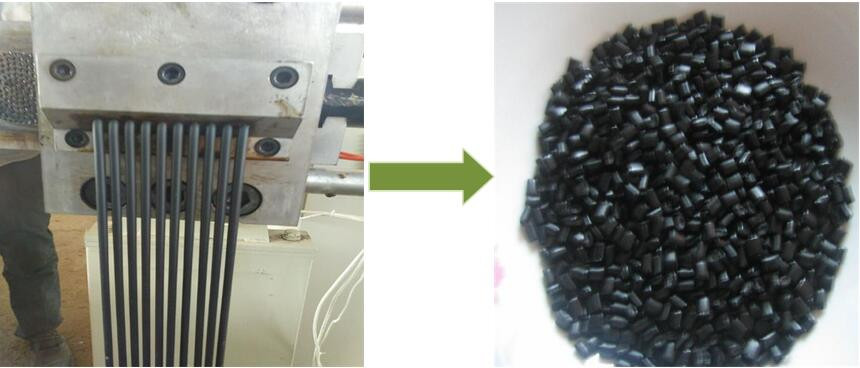

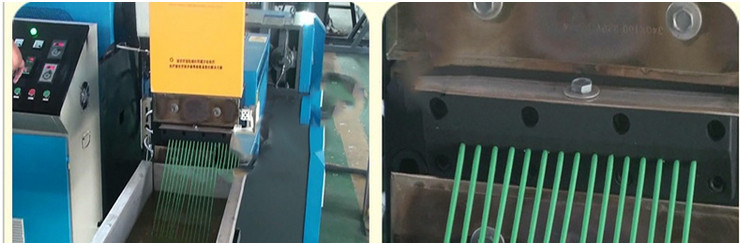

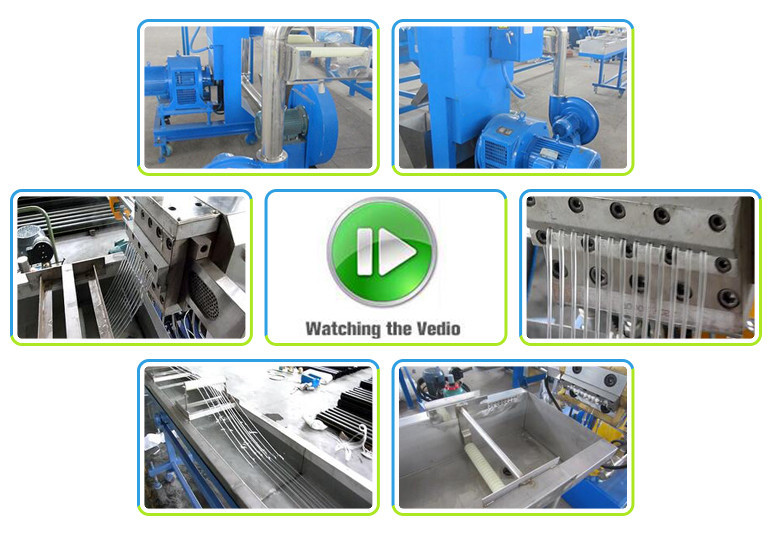

- Water cooling stand plastic pelletizing machine

- Min Order

- 1 set

- brand name

- EVERGRAND

- Nearest port for product export

- Qingdao, Tianjin, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Westem Union

- update time

- Wed, 20 Nov 2019 21:43:58 GMT

Paramtents

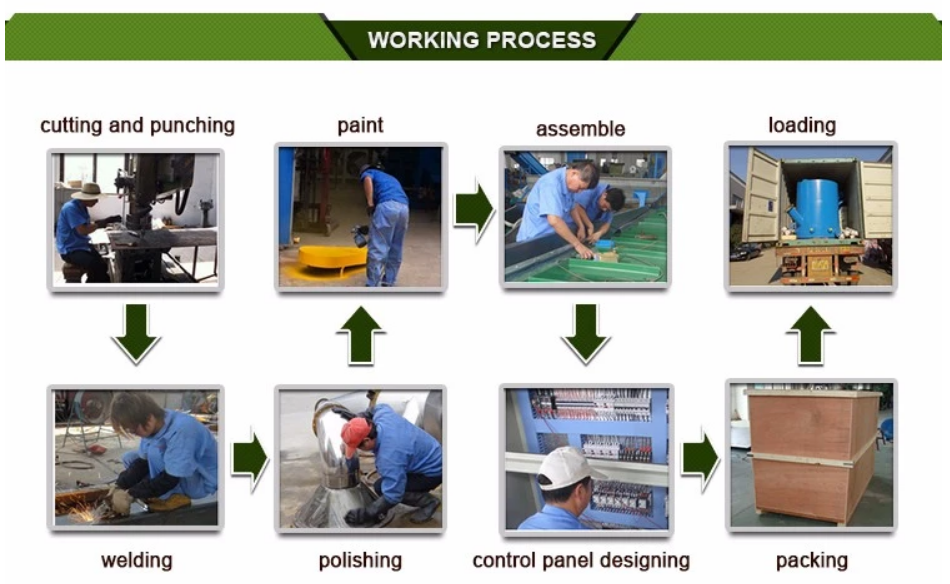

After-sales Service Provided Engineers available to service machinery overseas

Capacity 80-1000kg/h

Equipment material iron, stainless steel

Raw material pp/pe/ldpe/hdpe film

Qulaity assured 2 years

Application hdpe compounding granules

color according to your need

Packging & Delivery

-

Min Order1 set

Briefing

Lower power consumption

Good quality with reasonable price

Long lifespan

Detailed

Advantages:

1. Increasing the operation variables and realizing the process because of two-stage machine.

2. High effective and production capacity.

3. Good at process heat-sensitive material and devolatilization operation, Such as PVC, XLPE.