Search This Supplers Products:Plastic recycling pelletizing machinePlastic corrugated pipe machinePlastic crusherPlastic label remover

Waste Plastic Washing And Crushing Machine Line Plastic Recycling Equipment

- group name

- Plastic PET Bottles Recycling Washing Line

- Min Order

- 1 set

- brand name

- EVERGRAND

- Nearest port for product export

- Qingdao, Tianjin, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Westem Union

- update time

- Tue, 12 Nov 2019 16:34:02 GMT

Paramtents

Capacity 300-2000kg/h

Washing type hot washing and cold washing

Final Flake Humidity less than 1%

Final product Clean PET flakes

Certification CE,ISO9001:2008

After-sales Service Engineers available to service machinery overseas

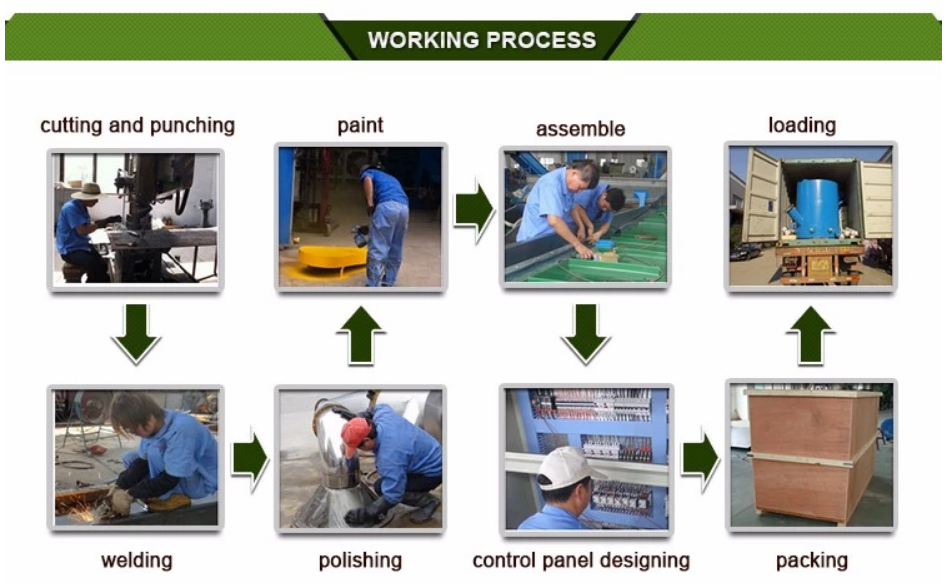

Packging & Delivery

-

Min Order1 set

Briefing

Widely used for plastic pet bottles

Long lifespan

Automatically

Detailed

Product capacity(kg/h) |

300 |

500 | 1000 |

1500 |

Workshop(L*W*H) |

40m*3m*3m |

40m*3m*3m | 60m*7.5m*3m |

75m*7.5m*3m |

Workers |

3-4 |

3-4 | 6-7 |

7-8 |

Water supply(tone/h) Recycle use |

2-3 |

3-5 | 7-10 |

10-14 |

Final product quality | Moisture: max 1% Bulk density: 0.3G/CM3 Particle size: 10-24mm Metal content: max.20ppm Floatable contamination: less than 200ppm | |||

Features Of Plastic Bottle Recycling Machine

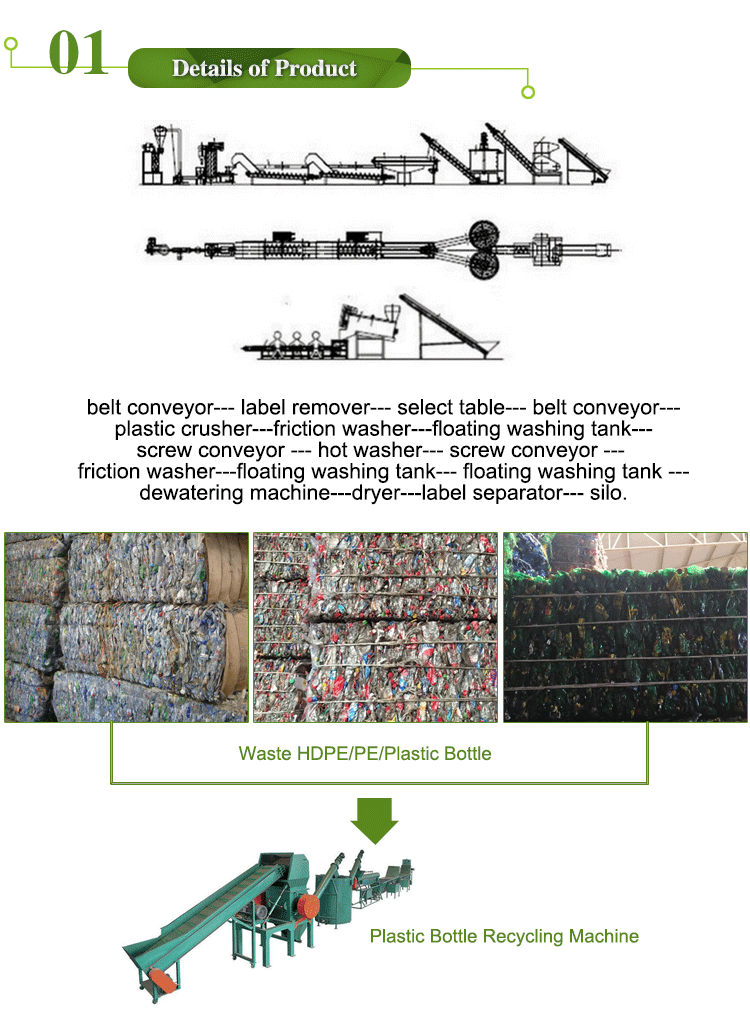

- Waste plastic pet bottle recycling machine plant of ISO9001 Standard is applied in PET waste bottle or sheet recycling field

- Through crushing, washing and dry process, the waste bottle or sheet will become to be bottle flakes. The flakes are widely used in plastic industry, like sheet, and profile production.

- The clean flakes can be used to produce the polyester staple fiber, PET strap band, granules, PET transparent film and sheets, etc. The top class flakes can be used to blow bottles again.

- Recycling machine can be designed on the basis of how dirty the flakes are, and make sure of the quality of the final products are very clean.

- Recycling machine output we can supply is from 200kg/h to 2000kg/h.

- We can also produce the plastic pipe extrusion line,plastic profile extrusion line,wood plast composite extruion line,plastic recycling productio line

- Welcome to visit us at any time and please feel free to contact us for more details.

- PET Bottle Flakes Recycling Washing Machine is highly automatic, and it is used for PET bottle crushing, washing, dryer and palletize.

- For PET palletizing, after being washed, dewatered and dried, the water content will be very low; PP/PE film after being washed can be directly granulated, the gained granules are even and smooth with shiny surface.

- Plastic recycle machine is widely used to treat PET bottle (coke bottles) and scrap PET plastic broken into flakes. It is a crushing, washing, drying line. PET flakes are mainly used for the fiber production and other related PET products.

- This production line is high automatic operating and save labor cost and low after maintenance. With advanced international industry concepts and technologies to meet waste plastic recycling at home or abroad.

· Pre-sale: we given client the details technician offer, sign the sales contract etc.

· In-sales: we supply the details layout, installation instruction, technician support for the clients;

· After sales: we arrange engineer to install the machinery and training the workers for client;

· We have 24hours team to solve the after sales problem;

· We have free spare parts with the machine;

· We supply long term spare parts for every customer

· We always up date the new technology to every customer